2124 aluminum blocks

The characteristics of 2124 aluminum blocks are: high strength, a certain degree of heat resistance, and can be used as working parts below 150°C. At temperatures higher than 125°C, the strength of 2124 alloy is higher than that of 7075 alloy. In hot state, annealing and new quenching state, the forming performance is better, and the heat treatment strengthening effect is obvious, but the heat treatment process is strict. The corrosion resistance is poor, but it can be effectively protected by covering with pure aluminum; it is easy to produce cracks during welding, but it can be welded or riveted by special technology.

The chemical composition of 2124 aluminum blocks:

Silicon: 0.5%

Iron: 0.5%

Copper: 3.8-4.9: 0.5%

Iron: 0.5%

Copper: 3.8-4.9

Manganese: 0.3-0.9

Magnesium: 1.2-1.8

Chromium: 0.10

nickel:-

Zinc: 0.25

Titanium: 0.15

Other: 0.15

Aluminum: the rest

Application of 2124 aluminum blocks:

2124 aluminum blocks are widely used in aircraft structures, rivets, truck wheel hubs, propeller components and various other structural parts.

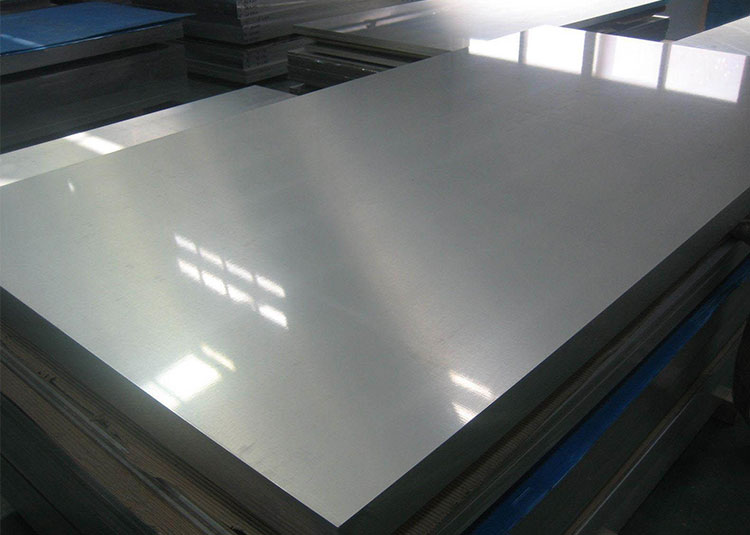

Aluminium Sheets

View Details

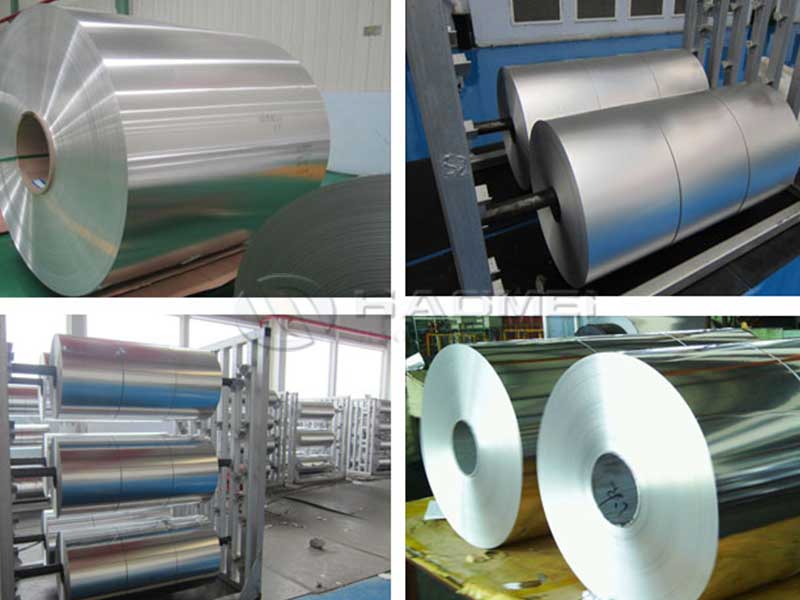

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

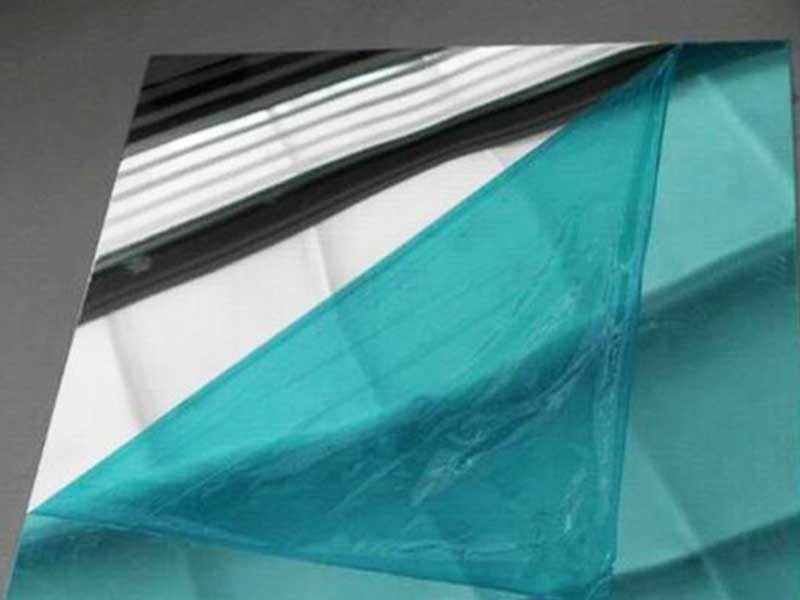

Mirror Aluminum

View Details

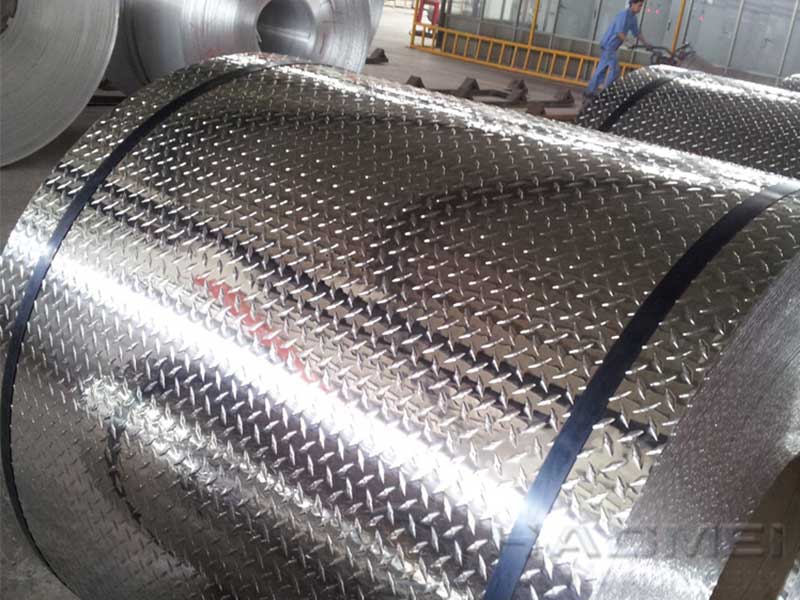

Stucco Embossed Aluminum

View DetailsAluminum

- Aluminum sheet /aluminum plate...

- 5052 5182 Aluminum Cap Strip F...

- Aluminium sign board supplier

- 1060 aluminium foil for soft c...

- metal aluminum jacketing

- 1100 H22 8011 H22 hydrophobic...

- Aluminum Foil 5052 H18

- Common Term for Aluminum Plate

- The harm of aluminium pot, ple...

- 2219 Aluminum plate

- 1050 Aluminum Sheet

- mirror aluminum coil sheet for...

- 2024 T3511 Aluminum Sheet Plat...

- How to make outdoor aluminum s...

- 3003 3105 Coated Aluminum Coil

- 1100 Aluminum tread plate

- 2024 T351 aluminum alloy plate...

- Aluminum sign board price

- Architecture Anodized Coil

- Production and construction of...