Advantages of anodized aluminum mirror coil:

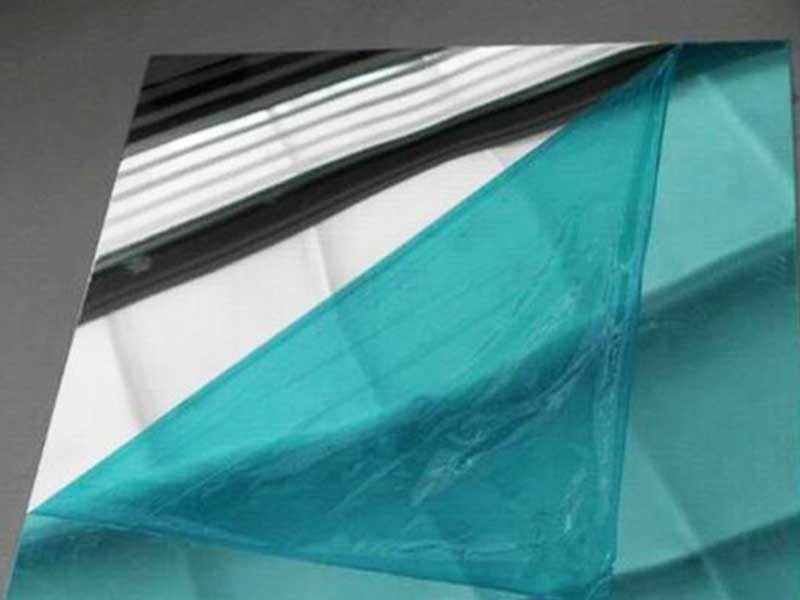

1. The transparent mirror anodic oxide film retains the metallic appearance, and the natural soft metallic texture of aluminium is fully retained.

2. Dense oxide film was formed on metal surface by anodic oxidation process, which has good corrosion resistance.

3. The oxide film will never fall off. Overseas, it has been applied in various fields for 40 years.

4. Scratch resistance of oxide film, surface hardness up to sapphire grade, micromolar hardness 9 grade (diamond 10 grade)

5. Light weight, high strength, only one third of the proportion of stainless steel

6. Surface without charge, no dust, easy to clean, after several times of cleaning, still clean as new, strong anti-fingerprint ability.

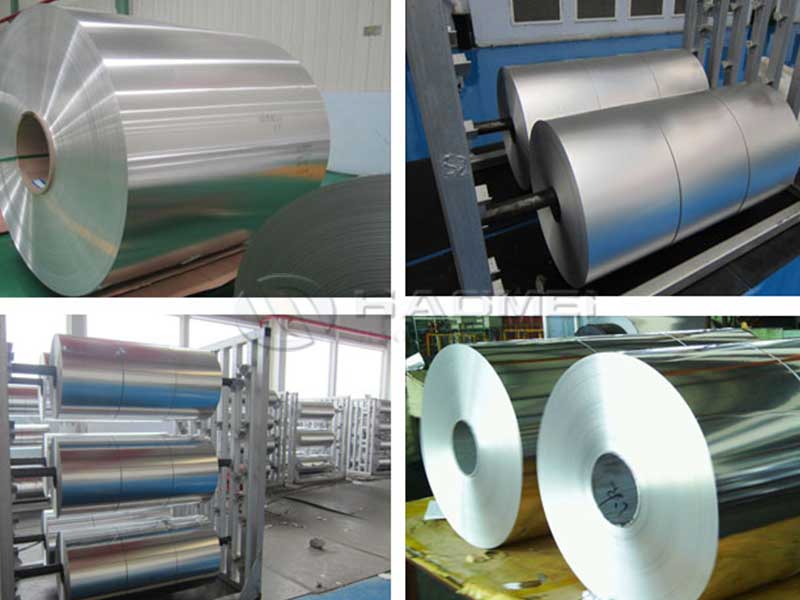

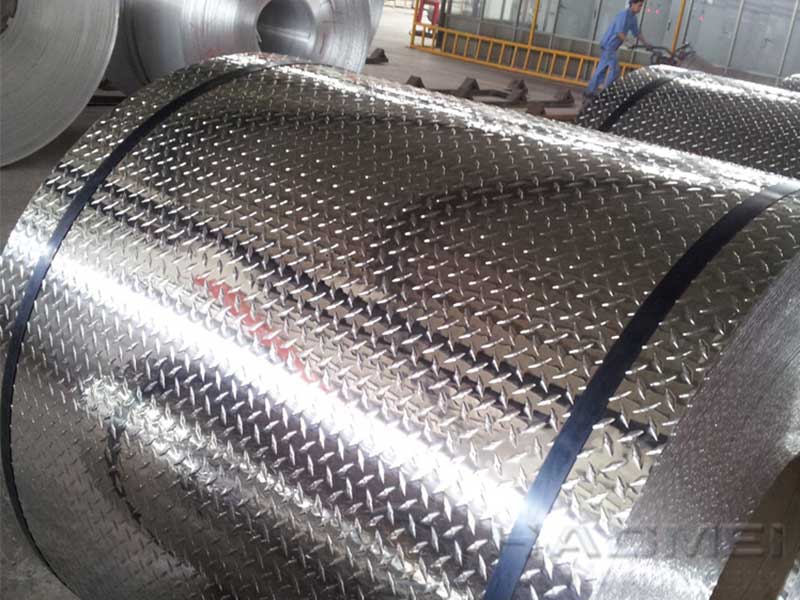

7. Coil processing, good surface consistency.

8. Good processability.