1100 1050 H22 1.0MM aluminum strip for Car License Plate

Aluminium Strips / Flat Aluminium Strip in China

| Technical Specification Aluminium | Date - 4.03.2016 | ||

| S. No. | Characteristics | Specification of Material | Supplier Test reports Required with every Lot |

| A | Alloy Designation | EN AW 1050A as per DIN 74069 | Chemical Composition Test Report |

| B | Chemical Composition | In Percentage by mass | |

| 1 | Al | 99.5 min. | |

| 2 | Si | 0.25 Max | |

| 3 | Fe | 0.40 Max | |

| 4 | Cu | 0.05 max. | |

| 5 | Mn | 0.05 max | |

| 6 | Zn | 0.07 max. | |

| 7 | Other : Each | 0.03 max. | |

| 8 | Other : Total | 0.15 max. | |

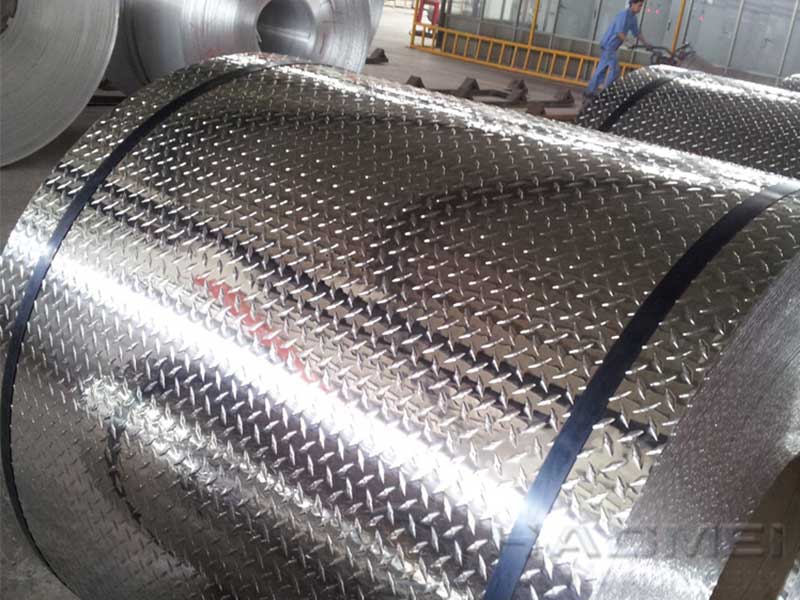

| C | Dimension of Aluminium Coil | Dimensional Parameters Test Report | |

| 1 | Width of sheet | ||

| 2 | SU-AL01 | 46.2 -0.2 mm | |

| 3 | SU-AL02 | 101.2 -0.2 mm | |

| 4 | SU-AL03 | 121.2 -0.2 mm | |

| 5 | SU-AL04 | 201.2 -0.2 mm | |

| 2 | Thickness | 1.0 mm - 0.03 mm | |

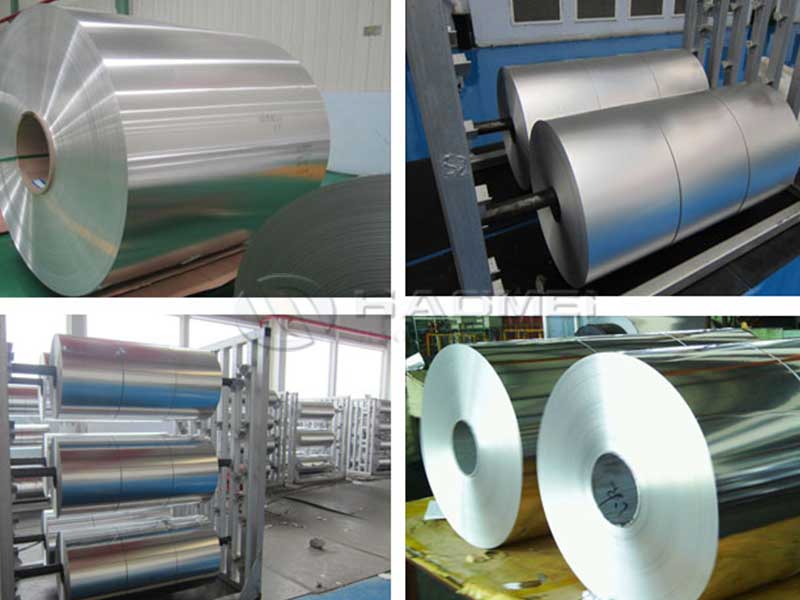

| 3 | Coil O. D. | 1830mm / 1220mm | |

| 4 | Coil I. D. | 500 mm | |

| 5 | Straight lining | 4 – 8 mm for length 2000 mm & 5000 mm | |

| D | Mechanical Properties | ||

| 1 | Temper | H22 | Temper Grade Test Report |

| 2 | Tensile Strength (Mpa) | 85 – 125 | Mechanical Parameters Test Report |

| 3 | Proof Stress Rp 0.2 (Mpa) | 55 | |

| 4 |

Elongation min.% A 50 mm |

5% | |

| 5 | Bend Radius at 180° | 0.5t | |

| Bend Radius at 90° | 0t | ||

| 6 | Hardness (HBS) | 27 | |

| E | Wire edge condition | Free from burr or wired edge | Visual |

| F | Coating |

Top side of aluminum coil –Degreased & Chromatising should be ≥ 25-30 mg Cr/sqm. Lower side of aluminum coil – Degreased, Chromating (≥ 25-30 mg Cr/sqm) and lacquering (thickness ≥ 2 microns) |

Coating Thickness Test Report |

| G | Salt Spray |

1. No Corrosion formation on aluminium surface. 2. Aluminium coil should pass the salt Spray test mentioned in DIN 50021 for 120 Hrs. |

Salt Spray Test Report for 120 Hrs. |

| H | Surface Condition | Must be free from oil, scratches, dirt, and stain marks | Visual |

| Packing Standard | |||

| 96+ | Method of Packing |

1. Four Aluminium coils are placed horizontally between two Wooden Octagonal pallets. 2. Wooden pallet should be provided with minimum ground clearance of 100mm. |

For material Packing |

| Length of a side of Octagonal Wooden Pallet | 810 mm ± 2 mm , 585 mm ± 2 mm | ||

| Thickness of wooden pallet | 45 mm ± 2 mm | ||

| Separation between Aluminium Coils | Two Aluminium coils are separated by 4 wooden blocks. | ||

| Size of wooden Block | (500 x 65 x35 mm ) ± 2 mm | ||

| Preservation Method |

1. All the Rolls are covered with polythene of thickness 0.1 mm to protect it from moisture & dust. 2. The Coil has to be fastened with steel strips |

||