Production of copper clad busbar is specialized in the production of fully coated method, make the product form all around the package type copper aluminum composite material, than pure copper platoon light weight, the same specifications of copper clad busbar weighs only about 40% of the pure copper platoon.Copper clad aluminum metal processing performance is good, easy to bend, more copper has less rebound characteristics, easy drilling, cutting and punching, can be processed into various shaped mother row.

The copper clad aluminum plate produced by our company is evenly distributed, and the physical property is stable and reliable. It is a kind of resource saving product, which is specially designed to replace the pure copper platoon and the new material of pure aluminum platoon.It is widely used in all kinds of power equipment such as busbar, power distribution cabinet, switch cabinet, motor control center, busbar room, transformer and so on.

Copper clad busbar bus duct is a kind of pure busbar as core bus duct conductive row row, with a certain thickness of copper plate as outer conductor and installation interface bus duct conductive row, composition of copper clad aluminum bus duct conductive row.

This material in Europe already have decades of practical application, the international big companies such as ABB, will it as a strategic technology reserve and is widely used and early with standard specification in its list of their products.

Copper clad aluminum bus duct conductive row not only can instead of pure copper platoon bus duct conductive row, can also be applied in other in pure copper platoon as current situation, use the copper-coated busbar instead of the original copper platoon, effectively reduce the cost of the bus is about 50%.

Technical parameter :

Cladding strength : >=12N/mm;

Cladding rate : 100% ;

Cutting strength : >=35 Mpa;

Stretch strength : 90—130 Mpa;

Elongation : <=35% ;

Direct Current resistivity : <=0.0245 O.mm2/m

Continuous Casting

- High bonding-Strength; Metallurgical & Atomic

- The Length at option of requirement

- Short Production Flow

- Continuous production with high efficiency

Other CCA Process

- Mechanical Bonding; Weak bonding Strength

- No large Size

- Limited length

- No continuous Production

Theoretical Table of Length & Weight

| Item | Size |

Thick /mm |

Width /mm |

Length /mm |

Volume /cm³ |

CCA BUSBAR | COPPER BAR | ||||

|

kgs/ meter |

Length m/MT |

Density g/cm³ |

kgs/ meter |

Length m/MT |

Density g/cm³ |

||||||

| 1 | 20*4 | 4 | 20 | 1000 | 81.93 | 0.37 | 2676.6 | 4.56 | 0.73 | 1372.94 | 8.89 |

| 2 | 25*4 | 4 | 25 | 1000 | 101.93 | 0.46 | 2151.4 | 4.56 | 0.91 | 1103.56 | 8.89 |

| 3 | 30*4 | 4 | 30 | 1000 | 121.93 | 0.56 | 1798.6 | 4.56 | 1.08 | 922.54 | 8.89 |

| 4 | 30*5 | 5 | 30 | 1000 | 151.93 | 0.69 | 1443.4 | 4.56 | 1.35 | 740.38 | 8.89 |

| 5 | 30*6 | 6 | 30 | 1000 | 181.93 | 0.83 | 1205.4 | 4.56 | 1.62 | 618.29 | 8.89 |

| 6 | 30*8 | 8 | 30 | 1000 | 241.93 | 1.1 | 906.5 | 4.56 | 2.15 | 464.95 | 8.89 |

| 7 | 30*10 | 10 | 30 | 1000 | 301.93 | 1.38 | 726.3 | 4.56 | 2.68 | 372.56 | 8.89 |

| 8 | 40*4 | 4 | 40 | 1000 | 161.93 | 0.74 | 1354.3 | 4.56 | 1.44 | 694.66 | 8.89 |

| 9 | 40*5 | 5 | 40 | 1000 | 201.93 | 0.92 | 1086 | 4.56 | 1.8 | 557.05 | 8.89 |

| 10 | 40*6 | 6 | 40 | 1000 | 241.93 | 1.1 | 906.5 | 4.56 | 2.15 | 464.95 | 8.89 |

| 11 | 40*8 | 8 | 40 | 1000 | 321.93 | 1.47 | 681.2 | 4.56 | 2.86 | 349.41 | 8.89 |

| 12 | 40*10 | 10 | 40 | 1000 | 401.93 | 1.83 | 545.6 | 4.56 | 3.57 | 279.86 | 8.89 |

| 13 | 50*5 | 5 | 50 | 1000 | 251.93 | 1.07 | 934 | 4.25 | 2.24 | 446.5 | 8.89 |

| 14 | 50*6 | 6 | 50 | 1000 | 301.93 | 1.28 | 779.3 | 4.25 | 2.68 | 372.56 | 8.89 |

| 15 | 50*8 | 8 | 50 | 1000 | 401.93 | 1.71 | 585.4 | 4.25 | 3.57 | 279.86 | 8.89 |

| 16 | 50*10 | 10 | 50 | 1000 | 501.93 | 2.13 | 468.8 | 4.25 | 4.46 | 224.11 | 8.89 |

| 17 | 60*5 | 5 | 60 | 1000 | 301.93 | 1.28 | 779.3 | 4.25 | 2.68 | 372.56 | 8.89 |

| 18 | 60*6 | 6 | 60 | 1000 | 361.93 | 1.54 | 650.1 | 4.25 | 3.22 | 310.79 | 8.89 |

| 19 | 60*8 | 8 | 60 | 1000 | 481.93 | 2.05 | 488.2 | 4.25 | 4.28 | 233.41 | 8.89 |

| 20 | 60*10 | 10 | 60 | 1000 | 601.93 | 2.56 | 390.9 | 4.25 | 5.35 | 186.88 | 8.89 |

| 21 | 80*6 | 6 | 80 | 1000 | 481.93 | 2.05 | 488.2 | 4.25 | 4.28 | 233.41 | 8.89 |

| 22 | 80*8 | 8 | 80 | 1000 | 641.93 | 2.73 | 366.5 | 4.25 | 5.71 | 175.23 | 8.89 |

| 23 | 80*10 | 10 | 80 | 1000 | 801.93 | 3.41 | 293.4 | 4.25 | 7.13 | 140.27 | 8.89 |

| 24 | 100*6 | 6 | 100 | 1000 | 601.93 | 2.56 | 390.9 | 4.25 | 5.35 | 186.88 | 8.89 |

| 25 | 100*8 | 8 | 100 | 1000 | 801.93 | 3.41 | 293.4 | 4.25 | 7.13 | 140.27 | 8.89 |

| 26 | 100*10 | 10 | 100 | 1000 | 1001.93 | 4.26 | 234.8 | 4.25 | 8.91 | 112.27 | 8.89 |

| 27 | 120*8 | 8 | 120 | 1000 | 961.93 | 4.09 | 244.6 | 4.25 | 8.55 | 116.94 | 8.89 |

| 28 | 120*10 | 10 | 120 | 1000 | 1201.93 | 5.11 | 195.8 | 4.25 | 10.69 | 93.59 | 8.89 |

Current Carrying Capacity & Temperature Rise Table of CCA Busbar

| (Width× Thickness) | Temperature rise(K) under Ambient Temperature25 ℃ (Amperes) | |||||

| mm× mm | VPCu =25% | VPCu =30% | ||||

| 50K | 65K | 75K | 50K | 65K | 75K | |

| 15.00×4.00 | 196 | 210 | 225 | 200 | 213 | 229 |

| 20.00×4.00 | 254 | 273 | 293 | 259 | 277 | 298 |

| 25.00×4.00 | 314 | 339 | 363 | 321 | 345 | 370 |

| 30.00×4.00 | 336 | 362 | 387 | 347 | 372 | 399 |

| 30.00×5.00 | 438 | 453 | 489 | 450 | 466 | 503 |

| 30.00×6.00 | 499 | 539 | 579 | 514 | 554 | 595 |

| 30.00×8.00 | 596 | 644 | 697 | 613 | 662 | 717 |

| 30.00×10.00 | 658 | 712 | 745 | 676 | 733 | 767 |

| 40.00×4.00 | 465 | 500 | 532 | 479 | 513 | 547 |

| 40.00×5.00 | 554 | 605 | 652 | 570 | 622 | 670 |

| 40.00×6.00 | 630 | 679 | 728 | 649 | 698 | 750 |

| 40.00×8.00 | 746 | 806 | 873 | 767 | 829 | 897 |

| 40.00×10.00 | 814 | 896 | 977 | 837 | 921 | 1005 |

| 50.00×5.00 | 684 | 736 | 788 | 703 | 758 | 810 |

| 50.00×6.00 | 777 | 836 | 898 | 799 | 861 | 923 |

| 50.00×8.00 | 918 | 990 | 1072 | 944 | 1019 | 1103 |

| 50.00×10.00 | 998 | 1061 | 1139 | 1026 | 1092 | 1172 |

| 60.00×5.00 | 781 | 858 | 918 | 804 | 882 |

945<

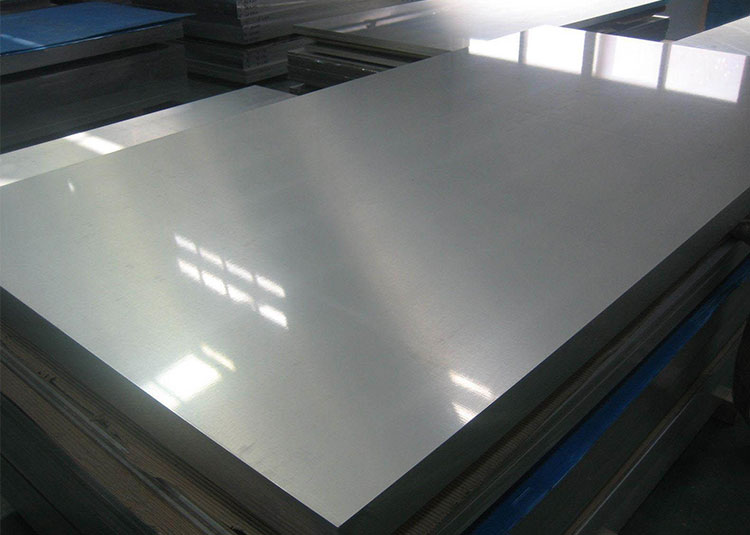

Aluminium SheetsView Details

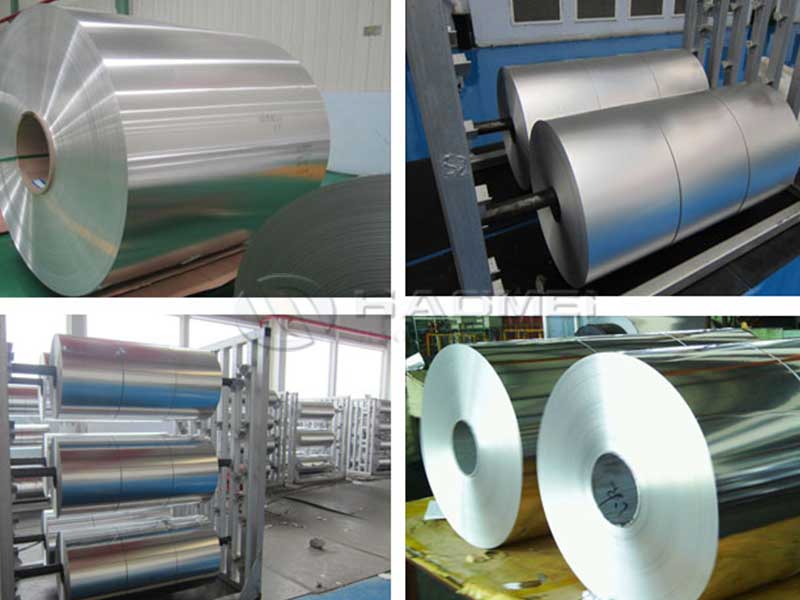

Aluminium CoilsView Details

Aluminium FoilsView Details

Aluminium StripsView Details

Aluminium CirclesView Details

Coated AluminiumView Details

Mirror AluminumView Details

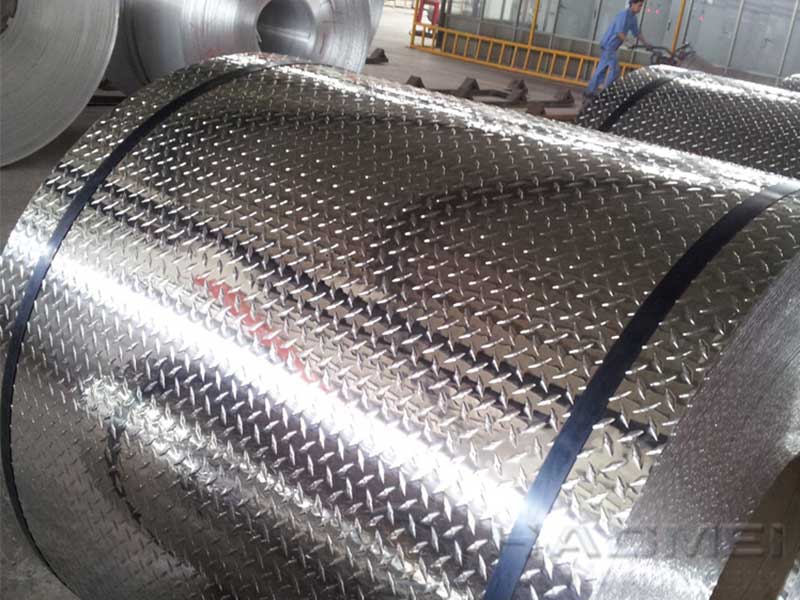

Stucco Embossed AluminumView DetailsCopper

|