copper clad aluminum bus bars

In the power transmission and distribution equipment, the bending stress caused by its own weight is much smaller than that of copper, but the aluminum surface is very easy to oxidize and is prone to failure at the connection. For a long time, the amount is less. After the aluminum surface is oxidized, an insulating layer is formed, and the contact resistance increases and generates heat. The heat intensifies the oxidation speed, resulting in a vicious cycle, resulting in power failure or even burning of the contact surface. The aluminum bar must be replaced after about 10 years of service.

Use of copper bars

Due to the contradiction between the shortage of copper resources and the rapid growth of consumption, copper prices have soared unprecedentedly all over the world in recent years. Millions of tons of copper bus are needed every year. Copper surface has strong oxidation resistance, and it still has conductivity after oxidation, which has little impact on power supply safety. The copper bar has been used for more than 30 years.

Research and application of copper clad aluminum bus bars

The utility model relates to a copper aluminum composite bus made of copper for the outer layer and aluminum for the inner core, which not only maintains the characteristics of strong oxidation resistance on the surface of copper bus, but also makes full use of the advantages of light weight and low price of aluminum. Due to the influence of skin effect, its conductivity is much higher than aluminum and slightly lower than copper. It is the best material to replace copper bus. It has high conductivity, light weight and low price, and the tensile strength, elongation and bending properties can meet the requirements of electrical equipment. However, the copper and aluminum composite interface of this composite must meet the metallurgical bonding, and the interface has sufficient strength. Copper clad aluminum bus bars is a new conductive material. Its service life should be the same as that of copper bar, but it needs time to test and prove.

Copper clad aluminum bus bars is a new type of conductive material. It began to be popularized in the market. It has achieved good economic benefits in saving material cost and reducing energy consumption. It has also been highly praised by professionals and passed a series of type tests. However, it is still necessary to constantly summarize the law and verify its scope of application in order to ensure its safe and effective application in the power supply system.

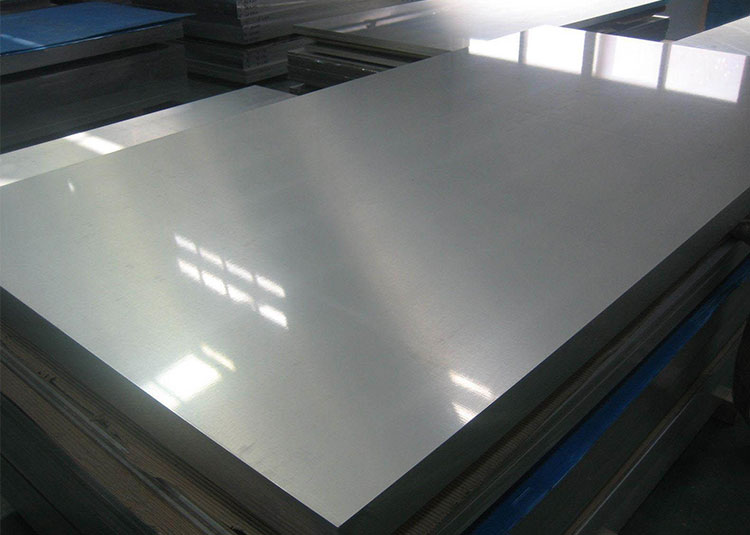

Aluminium Sheets

View Details

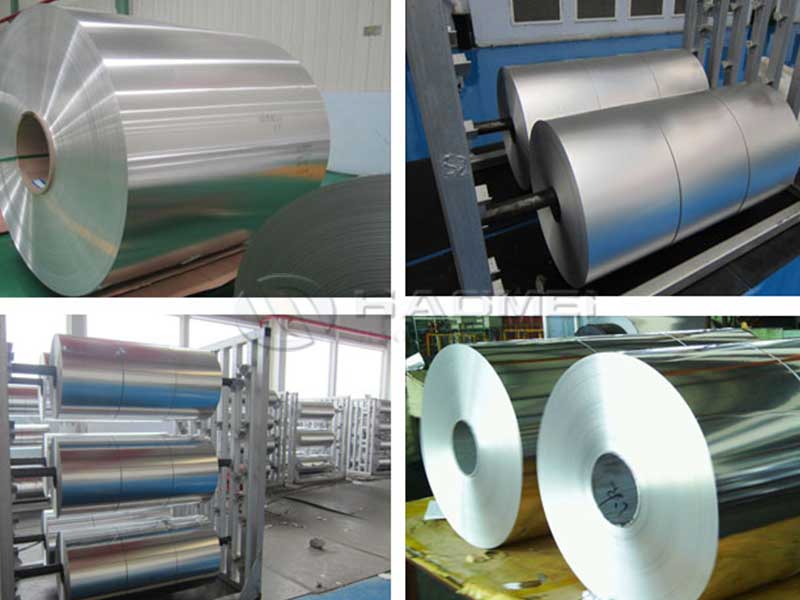

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

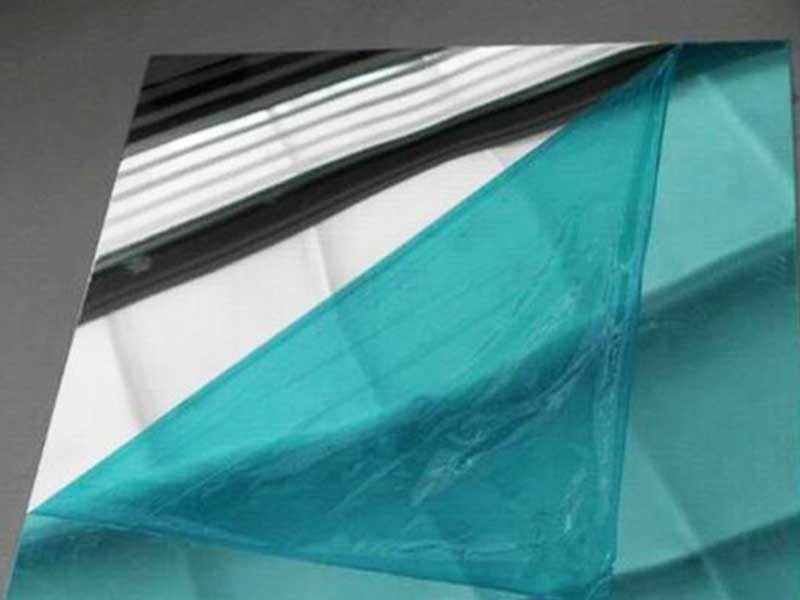

Mirror Aluminum

View Details

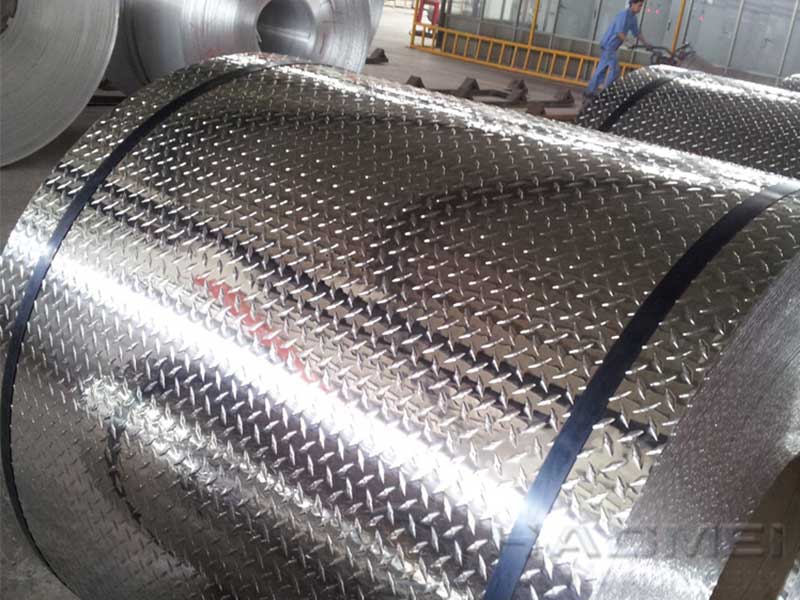

Stucco Embossed Aluminum

View DetailsCopper

- Copper clad aluminum wire 5654

- AgCu silver copper bimetal str...

- copper to aluminum bimetallic...

- Copper-aluminum composite radi...

- Silver plated copper clad alum...

- Copper clad aluminum bimetal s...

- copper clad aluminum conductor...

- High-current copper braid soft...

- Copper to aluminum bus bar

- Aluminum Copper Bimetal Connec...

- Copper clad aluminum wire’s ap...

- CCP Copper composite panel fea...

- single-sided copper clad alumi...

- CCA copper clad aluminum ename...

- aluminium copper bi metal term...

- copper washer on aluminum

- Copper foil soft connection ma...

- Three-layer copper aluminum co...

- Copper-Aluminium Bimetal Clad...

- Characteristics of titanium co...