The material of the new anode steel claws is low carbon steel, the anode steel claws beam is made of hot rolled thick plate, the anode steel claws beam is cut according to the size of the anode steel claws beam, the steel anode claws leg is made of rolled round rod, the steel anode claws leg is welded with the steel anode claws beam by special fusion welding technology to realize the metallurgical combination of full section.The application results in domestic electrolytic aluminum enterprises show that the new anode steel claws has higher conductivity and oxidation resistance than the ordinary cast steel claws, which can better meet the requirements of electrolytic aluminum production.

New anode steel claws for electrolytic aluminum

The material of the new anode steel claws is low carbon steel, the anode steel claws beam is made of hot rolled thick plate, the anode steel claws beam is cut according to the size of the anode steel claws beam, the steel anode claws leg is made of rolled round rod, the steel anode claws leg is welded with the steel anode claws beam by special fusion welding technology to realize the metallurgical combination of full section.The application results in domestic electrolytic aluminum enterprises show that the new anode steel claws has higher conductivity and oxidation resistance than the ordinary cast steel claws, which can better meet the requirements of electrolytic aluminum production.

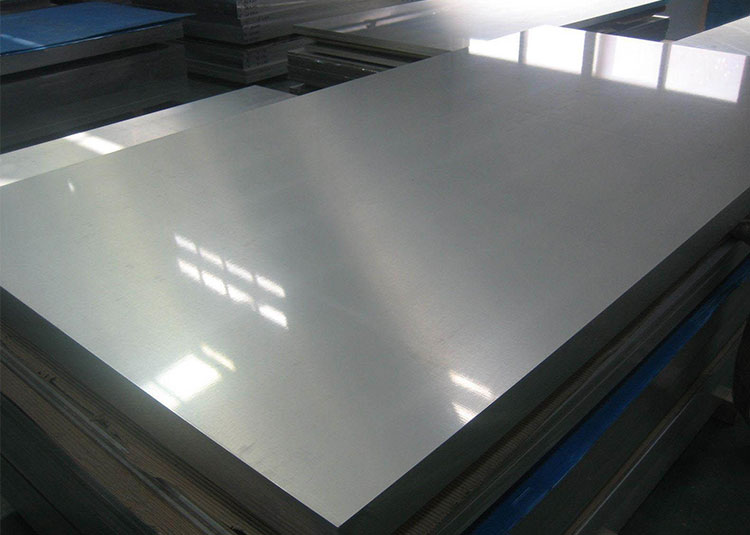

Aluminium Sheets

View Details

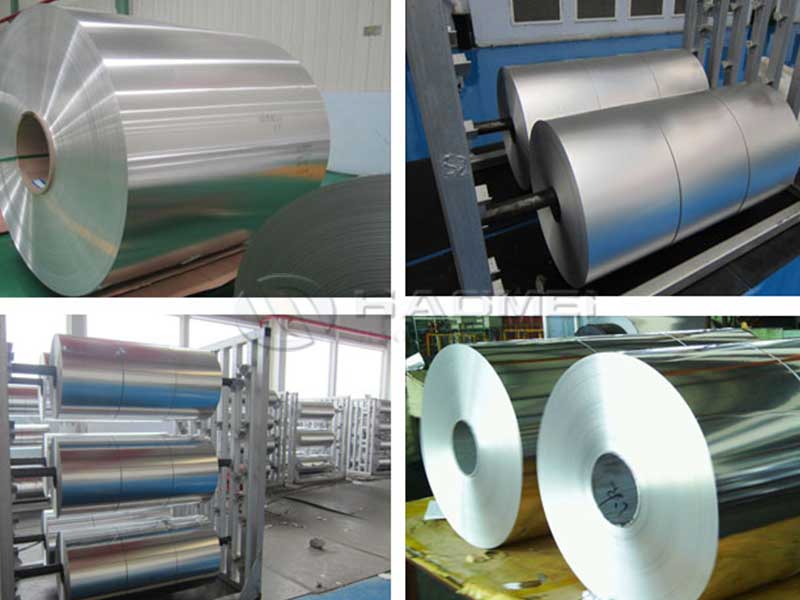

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

Mirror Aluminum

View Details

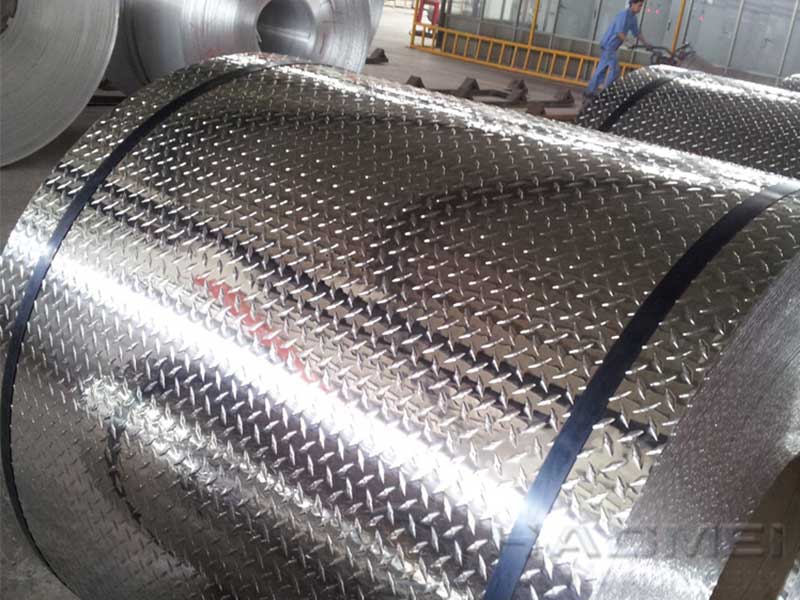

Stucco Embossed Aluminum

View DetailsSteel

- Process of Prebaked Anode Stee...

- Electrolytic steel claw

- Aluminum to stainless steel tr...

- Aluminum / Titanium / Carbon S...

- The anode steel claw

- aluminum clad steel coil strip

- Aluminum Steel Electrical Tran...

- Brass copper clad steel sheet...

- Titanium aluminum steel clad p...

- Ti Titanium clad steel plate

- Steel aluminum Triply Clad Cir...

- aluminum steel transition join...

- stainless steel aluminum clad...

- Three-layer copper stainless s...

- Steel aluminum transition join...

- stainless steel copper aluminu...

- armoured armor clad steel plat...

- Copper-steel clad sheet plate

- Monel carbon steel clad plate

- Aluminum Clad Steel Bimetal