Some questions about electrolytic aluminum production

Answer: electrolysis method for aluminum smelting is cryolite alumina melting salt electrolysis method. It takes cryolite as the solvent and alumina as the melting quality. Strong direct current flows into the electrolytic cell and electrochemical reactions take place on the cathode and anode.Electrolytic products, the cathode is aluminum solution, anode is CO2 and CO gas (carbon anode), this method is electrolytic aluminum smelting.

2. What is the raw material for electrolytic aluminum ?

Answer: electrolytic aluminum with raw materials roughly divided into three categories: material - alumina;Fluxing agent -- fluoride salt (including cryolite, aluminum fluoride, magnesium fluoride, calcium fluoride, etc.);Anode material -- pre-baked carbon block (pre-baked tank).

3. What is the purpose of direct current through electrolytic aluminum ?

Answer :Direct current is put into the electrolytic cell. On the one hand, it uses its heat energy to melt the cryolite into a molten state and maintains a certain electrolytic temperature.On the other hand, the first step is to finish the electrochemical reaction at the north and south poles, which means that the aluminum ions in the electrolyte can be separated from the cathode by gaining electrons, and then the aluminum ions can be discharged on the anode with the carbon to form a mixture of CO2 and CO.

4. What is the role of cryolite flux?

Answer: cryolite as electrolytic aluminum flux;Its function is: the front can better dissolve alumina, and the composition of the melt can be electrolyzed below the melting point of pure cryolite, and the flow is good;Secondly, at the electrolytic temperature, the density of cryolite alumina melt is 10% lower than that of aluminum melt, so the aluminum solution from electrolysis can be deposited on the cathode below the electrolyte, which can reduce the oxidation and loss of aluminum, and greatly simplify the structure of electrolytic aluminum cell.Third, cryolite has excellent electrical conductivity;Fourth, the cryolite is not rich in potential order than aluminum to correct the electrical metal impurities, can ensure the quality of the product aluminum, at that time, cryolite is still electrolytic aluminum production of a more ambition of a flux.

5, electrolytic aluminum why choose carbon anode?

Answer;In the process of electrolytic aluminum , the melt of cryolite with high temperature and high erosive property is in direct contact with the electrode.As a conductive Cathode & Anode north and south of various guess, not only can excellent conductive, and high temperature resistance, corrosion resistance, with the price and low price only carbon materials.Therefore, aluminum industry production always choose carbon materials for the arctic and Antarctic.

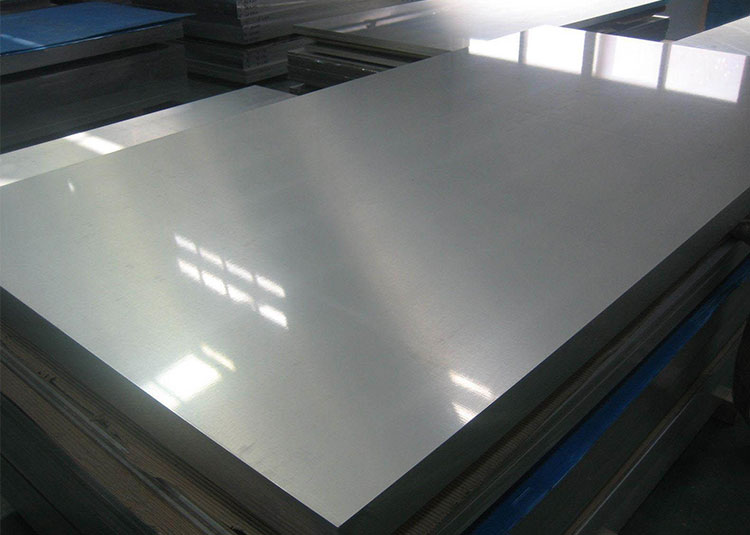

Aluminium Sheets

View Details

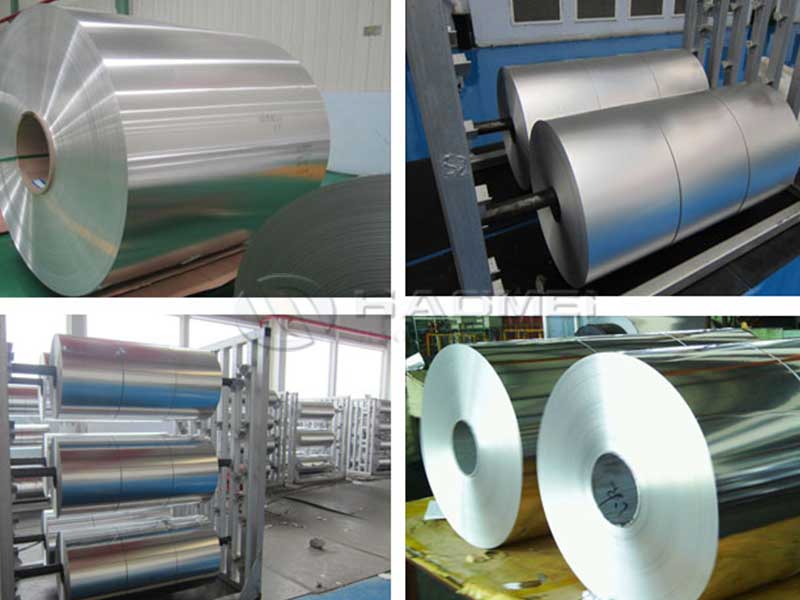

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

Mirror Aluminum

View Details

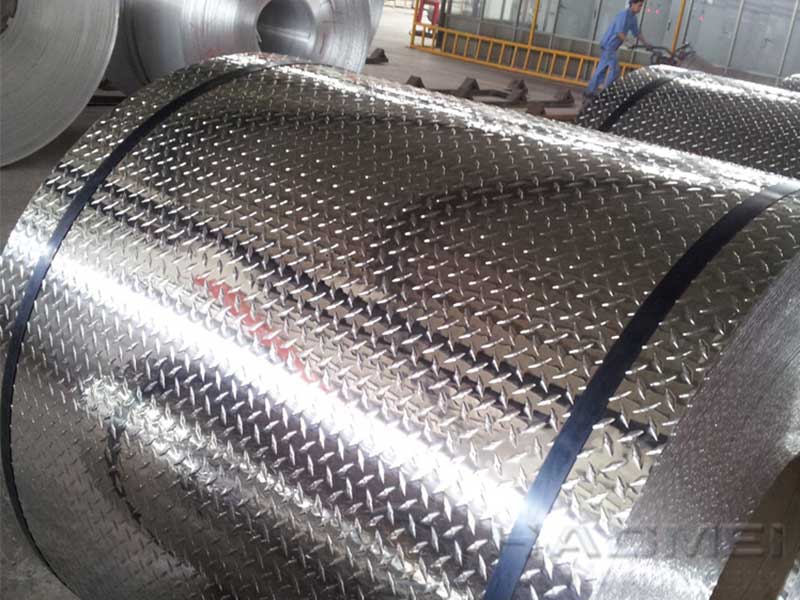

Stucco Embossed Aluminum

View DetailsAluminum

- 2198 aluminum-lithium alloy bl...

- What are the reasons for the o...

- Prebake anode carbon for elect...

- Application of aluminum circle...

- Aluminum model and specificat...

- 2017-t4 aluminum round bar

- Black aluminum sign blanks

- 12 round metal plate

- 5754 Aluminum Sign Blanks Shee...

- European Aluminum Foil Associa...

- Is the engine cast iron or alu...

- 4047 aluminium coil stock

- what type of aluminum are road...

- AL.INDUSTRIAL CO.,LTD PRODUC...

- Aluminum disc for traffic sign...

- 8011 O/H22/H24 aluminium foil...

- Flat bimetal bimetallic tube s...

- How to improve the performance...

- Introduction and Recognition o...

- Production Process of Aluminum...