2A06 aluminum bar rod

2A06 aluminum bar is high-strength hard aluminum, the pressure processing performance and machinability are the same as 2A12, and the plasticity is good under annealing and quenching conditions. 2A06 aluminum alloy can be quenched and aged. The general corrosion stability is the same as that of 2A12. When heated to 150-250 °C, the tendency to form intergranular corrosion is smaller than that of 2A12. The spot weldability is the same as that of 2A12 and 2A16. Argon arc welding Better than 2A12, but worse than 2A16.

Due to its high strength and good fatigue strength, 2A06 aluminum alloy rods are widely used in aircraft structures, rivets, truck hubs, propeller components and other structural components, especially under tension between the wing and fuselage structure.

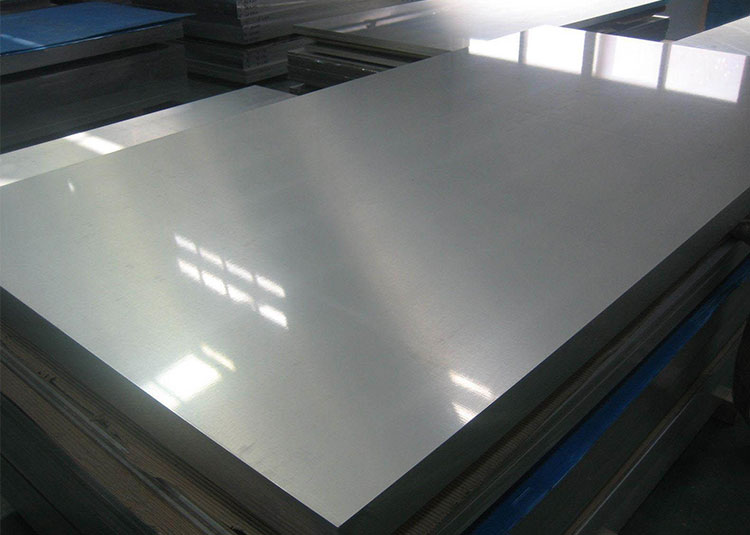

Aluminium Sheets

View Details

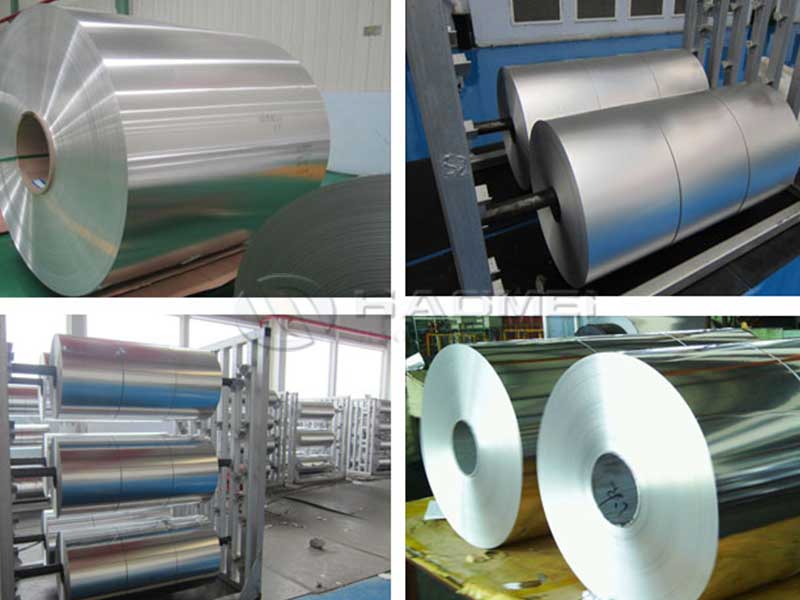

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

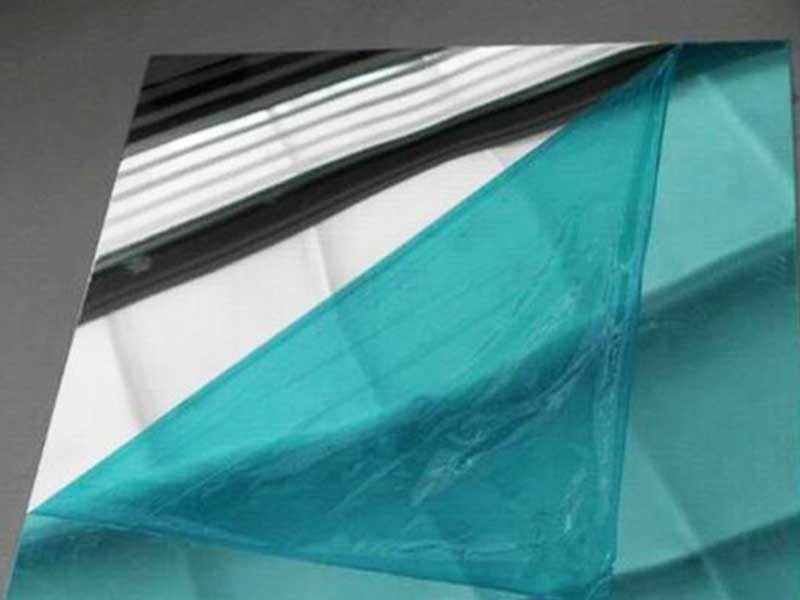

Mirror Aluminum

View Details

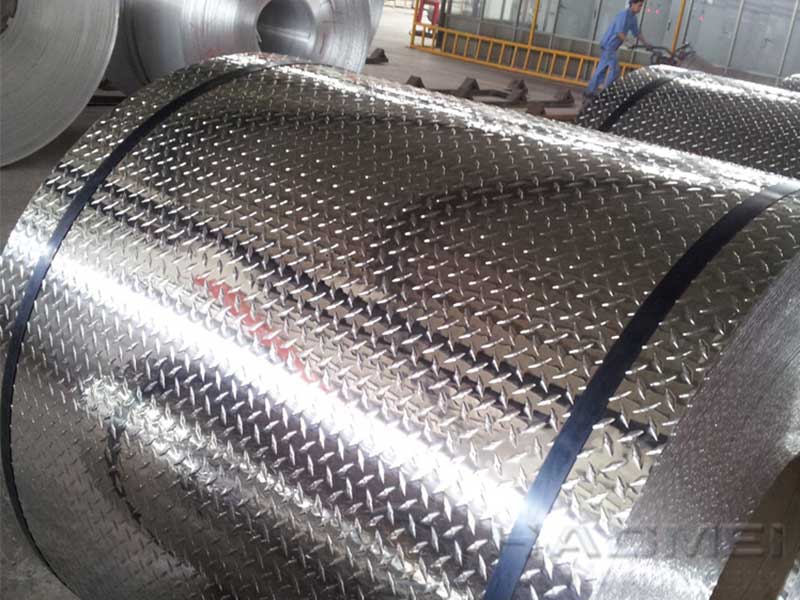

Stucco Embossed Aluminum

View DetailsAluminum

- Application fields of aluminum...

- 1235 O 0.0053mm 0.006mm flexi...

- what is the 2a12 aluminum roun...

- Anodized Aluminum Foil Strip f...

- large aluminum disc

- Transformer foil strip manufac...

- Anodized decorative aluminum s...

- pipe insulation cladding roll

- Pharmaceutical packing blister...

- tape aluminum foil ,8011 8079...

- Aluminum insulation jacketing...

- aluminum oxide discs

- aluminium winding wire manufac...

- 2024 T351 T651 T851 cold drawn...

- 6 Series Alloy Aluminum Rod

- battery grade aluminum foil

- 4x8 white aluminum sign board

- Aluminum frame wood plastic fo...

- Problems in the Use of High A...

- Best price 5005 H34 2.0*1200*2...