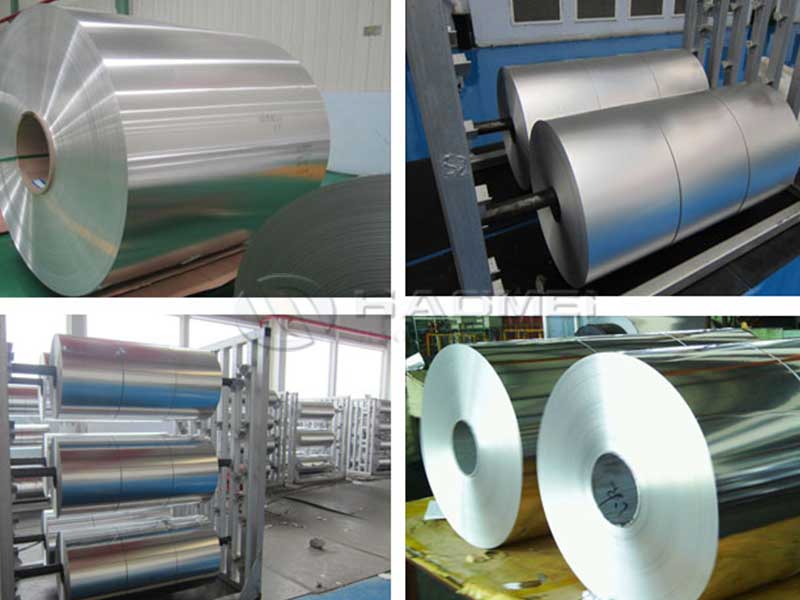

5052 Aluminium coil description

- Alloy:5052

- Temper:H32,H34,H38,H111,H112,H114,HO

- Mother coil:DC

- Thickness:0.5-6.0mm

- Width:100-2300mm

- MOQ:5ton per size

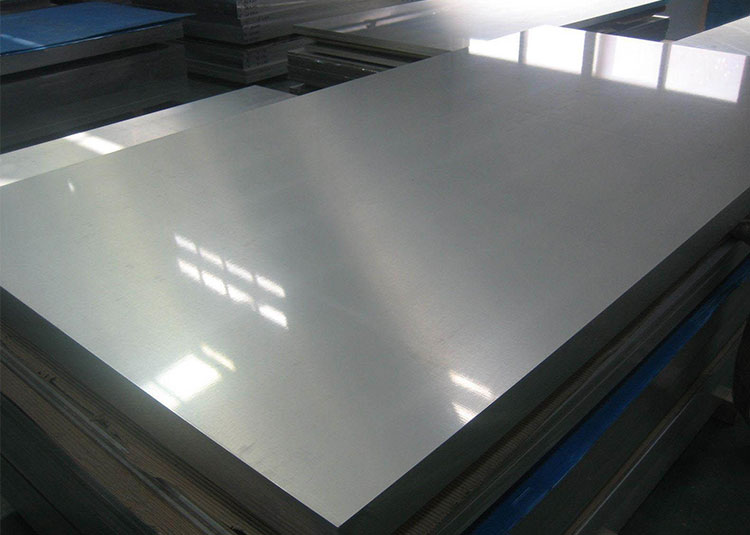

- Surface:clean and smooth,no bright speck,corrosion,oil,slotted,etc.

- Weigth:about 2mt per pallet

- Package:export standard package,wooden pallet with fumigation

- Package way:Eye to sky or Eye to wall

- Delivery time:about 30days after receiving the deposit

- Payment:TT

- Trading terms:FOB,CIF,CFR

- Product standard:GBT,JIS ,EN,ASTM

- We can supply the Form E, Form A,CO and so on

5052 Aluminium coil chemical composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | TI | |

| GBT/3190-2008 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.1 | 0.1 |

| Inner quality standard | 0.15 | 0.28-0.38 | 0.05 | 0.10 | 2.2-2.4 | 0.18-0.25 | 0.05 | 0.01-0.018 |

5052 Aluminium coil mechanical properties

| Thickness(mm) | Tensile strength(Mpa) | Yield strength(Mpa) | Elongtion(%) |

| 0.5-1.5 | 210-260 | 130 | 6 |

| 1.51-3.0 | 210-260 | 130 | 7 |

| 3.01-6.0 | 210-260 | 130 |

10 |

5052 Aluminium coil tolerance requirement

- Total weight: +/-10%

- Thickness:+/-1%

- Width:+2/-0mm

- Length:+3/-0mm

5052 Aluminium coil properties

- medium tenacity

- good corrosion resistance

- lower density

- high tensile strength

- high elongation

5052 Aluminium coil purpose

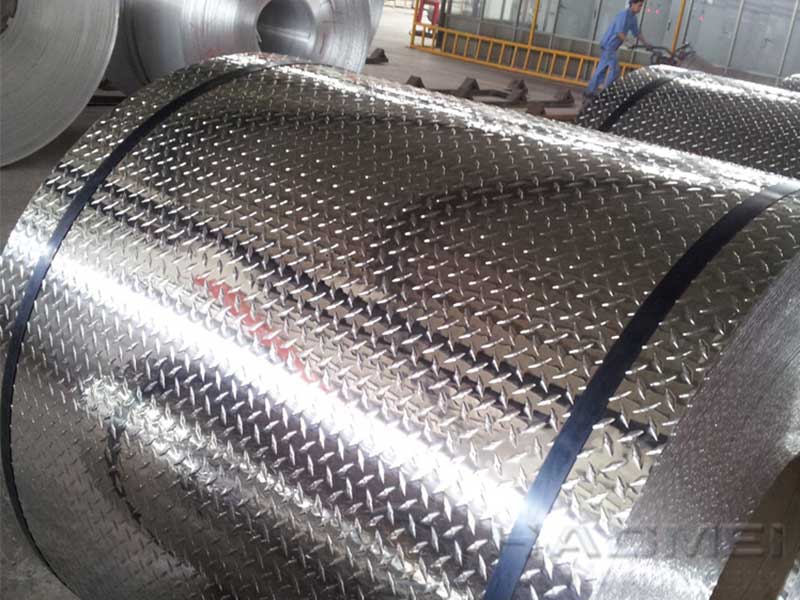

1.5052 aluminum coil widely used in making conductor,cookware,dash board,flooring,shell, building trim,construction materials,voiture materials.

2.5052 aluminum coil also used in construction material and building material.Including:roof panel,ceiling,in-wall, partition wall,shutters,window blind,gate,balcony,wall,road marking,

street signs,road protecting plate,highway protecting plate,bridge of barrier wall,scaffold,ship plate,etc.

Another alloy Aluminium coil

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.A1 |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.6 |

| 1070 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.7 |

| 1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.1 | - | - | - | 0.05 | 99 | |

| 1200 | 1.00 | 0.05 | 0.05 | - | - | - | 0.1 | - | - | 0.05 | 0.05 | 99 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.15 | Remainder |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | Remainder |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | - | 0.4 | - | - | 0.1 | 0.15 | Remainder |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | - | 0.25 | - | - | 0.1 | 0.15 | Remainder |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | - | 0.1 | - | - | 0.15 | 0.15 | Remainder |

| 3104 | 0.6 | 0.8 | 0.05-0.25 | 0.8-1.4 | 0.8-1.3 | - | - | 0.25 | - | - | 0.1 | 0.15 | Remainder |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | - | 0.25 | - | - | - | 0.05 | Remainder |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | - | - | 0.15 | 0.05 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | - | - | - | 0.05 | Remainder |

| 5182 | 0.2 | 0.35 | 0.15 | 0.2-0.5 | 4.0-5.0 | 0.1 | - | 0.25 | - | - | 0.1 | 0.05 | Remainder |

| 5754 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.05 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | - | - | 0.15 | 0.05 | Remainder |

| 7075 | 0.4 | 0.5 | 1..2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | - | 5.1-6.1 | - | - | 0.2 | 0.05 | Remainder |