Aluminimun and steel bi metal for ship building

In order to enhance the bonding between the two metals of aluminum steel explosive composite transition joint, a thin layer of metal material needs to be laid between the plates. Usually, pure titanium or pure aluminum is selected to form aluminum titanium steel or aluminum aluminum steel transition joint.

Aluminum and steel bi metal for ship building consists of three layers of metal materials, 5083, industrial pure aluminum and class D ordinary ship plate CCSD

The main alloy element of 5083 aluminum alloy is magnesium, which has good weldability, and the tensile strength can reach 350Mpa. After welding, the tensile strength can reach 270MPa. At present, aluminum magnesium alloy is mostly used in ship aluminum alloy superstructure. The yield strength of CCSD marine steel is not less than 235mpa, the tensile strength is 400-520mpa, and the intermediate layer is stored aluminum, and its tensile strength is 75-130mpa

When the aluminum alloy superstructure is connected with the steel hull through aluminum and steel bi metal for ship building, the high temperature generated by welding will promote the growth of intermetallic compounds at the aluminum steel interface, and form a thicker compound intermediate layer after multiple welding thermal cycles, which seriously reduces the bonding strength of the composite interface, Composite interface cracking is easy to occur, which endangers the performance and safety of ships. The critical temperature at the composite interface of aluminum aluminum steel is 300 ℃, and that of aluminum titanium steel is 350 ℃, and the performance index of aluminum titanium steel transition joint is higher than that of aluminum aluminum steel transition joint. In ship design, it is recommended to give priority to the use of aluminum titanium steel composite transition joint for ships with complex structure and high strength requirements.

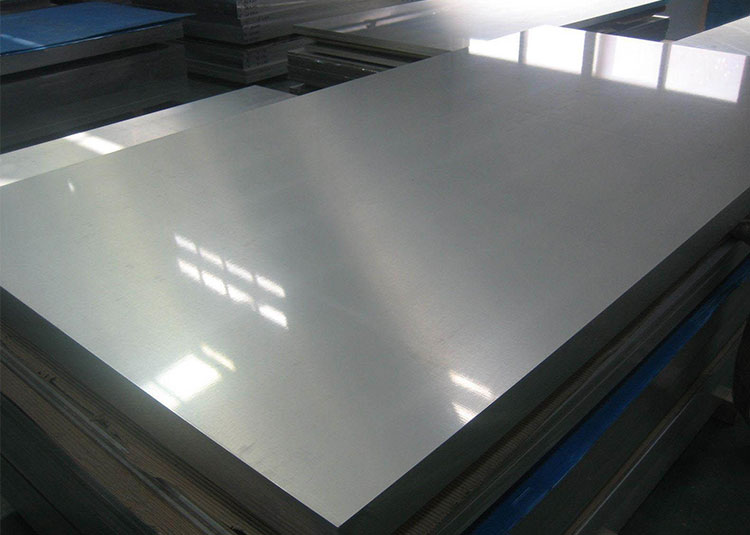

Aluminium Sheets

View Details

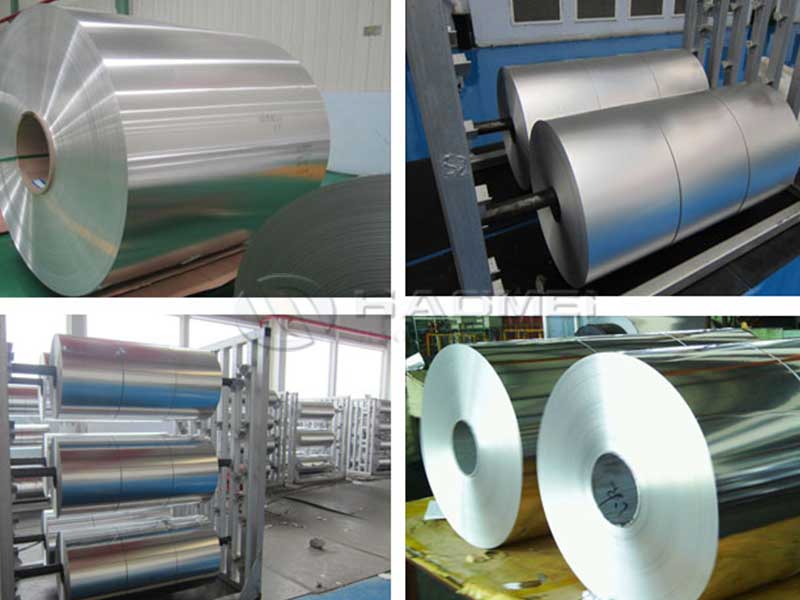

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

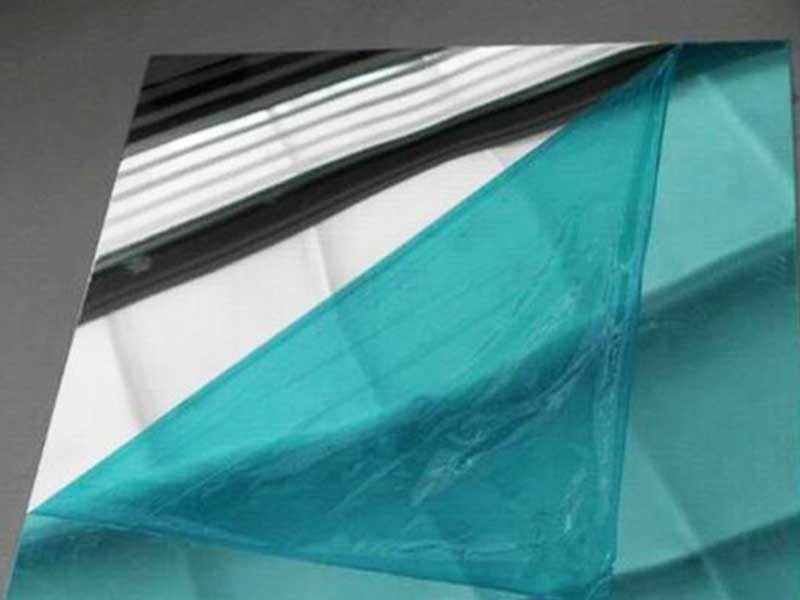

Mirror Aluminum

View Details

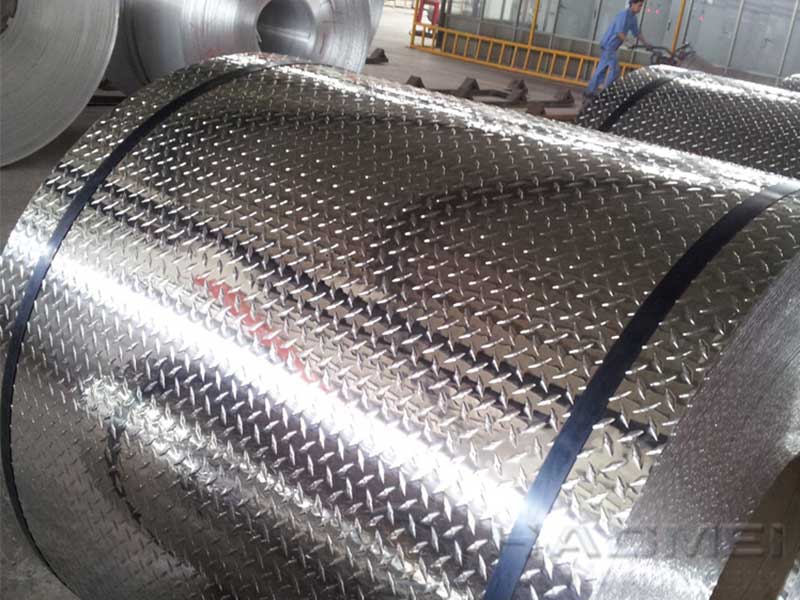

Stucco Embossed Aluminum

View DetailsSteel

- Titanium aluminum stainless st...

- Semi-trailer will realize from...

- stainless steel aluminum clad...

- aluminum steel transition join...

- Anode steel claw

- Characteristics of explosive c...

- carbon steel aluminum sheets

- cast steel anode yoke

- 5083 SS400 aluminum steel stru...

- Anodized steel jaw for electro...

- Aluminum Steel Electrical Tran...

- Explosion Bonded Copper Clad S...

- aluminum steel transition join...

- Steel anode claws china suppli...

- Cu Steel Bi-Metallic Plates

- Brass steel bimetal clad plate...

- Research on Effect of Steel Sh...

- Why is the anode steel claw re...

- Cast anode steel claw

- Explosion Welding Aluminium St...