aluminum-steel transition joints

As the aluminum-steel transition joints is composed of three different metal materials: aluminum alloy, aluminum and steel, the solubility between aluminum and steel is very low, and a variety of metal embrittlement phases will be formed when they fuse with each other. Under the action of welding stress, these intermetallic phases are easy to cause weld crack.Therefore, aluminum alloy as the cladding, aluminum as the intermediate layer, the hull structure steel as the base.

Generally used in high-speed ships on the construction of aluminum alloy (such as 5083,6082, etc.) have a ficant corrosion resistance, but if the ship is not built in accordance with the process requirements, after several years of use of the ship will still occur corrosion.

1. Spot corrosion.Aluminum pits in the ocean air and forms a very shallow gritty white powder on the entire surface.

2. Electrochemical corrosion.Metals with different electrode potentials in the electrolyte, the more negative metal will accelerate corrosion, while the more positive metal will be protected.

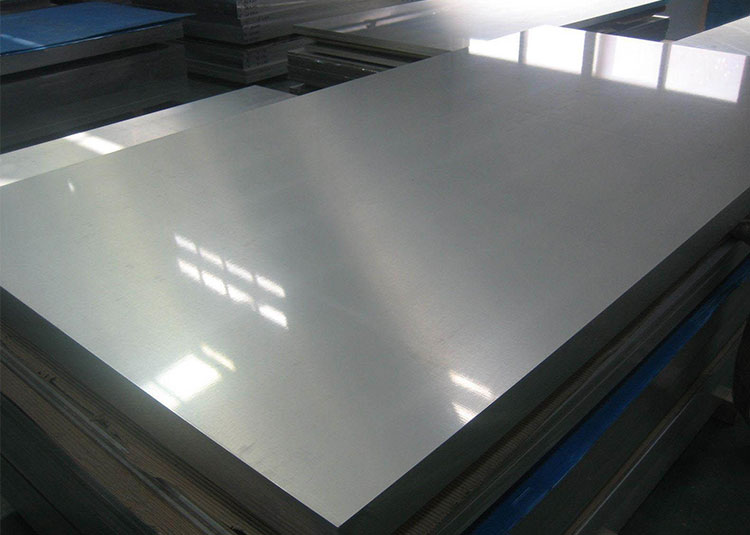

Aluminium Sheets

View Details

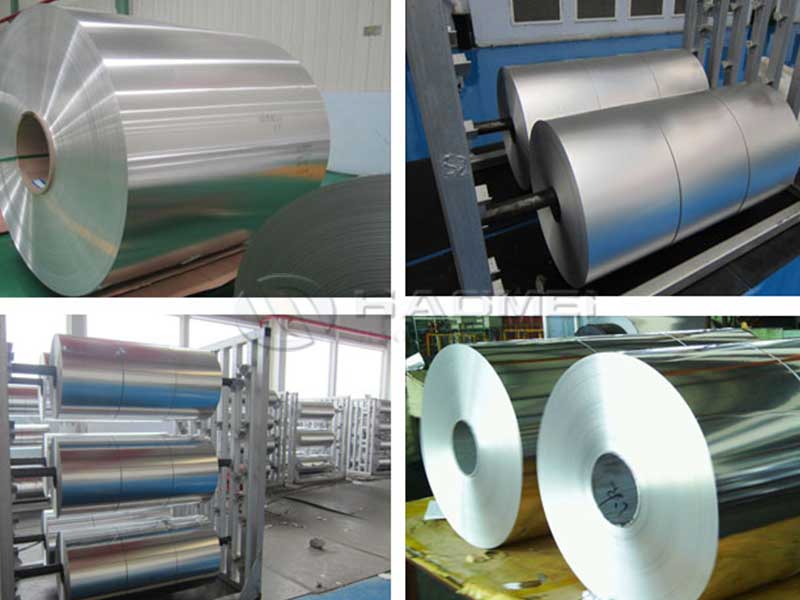

Aluminium Coils

View Details

Aluminium Foils

View Details

Aluminium Strips

View Details

Aluminium Circles

View Details

Coated Aluminium

View Details

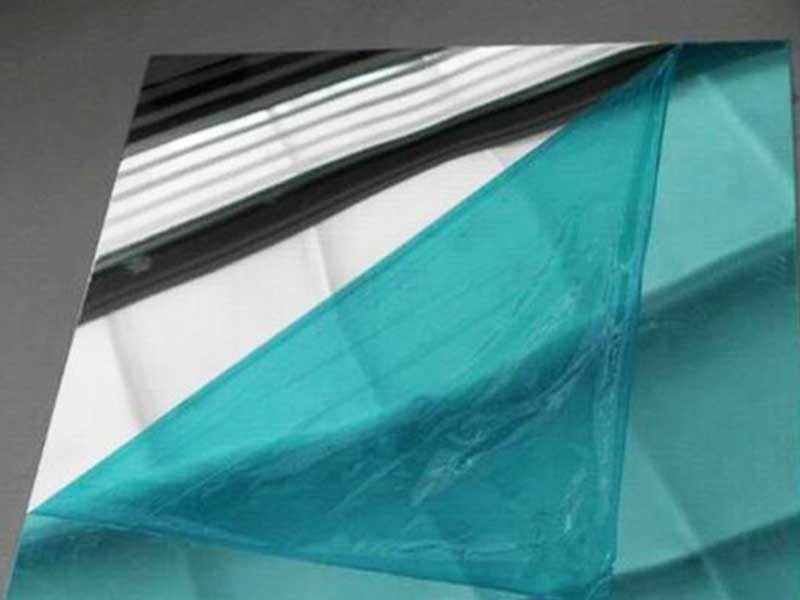

Mirror Aluminum

View Details

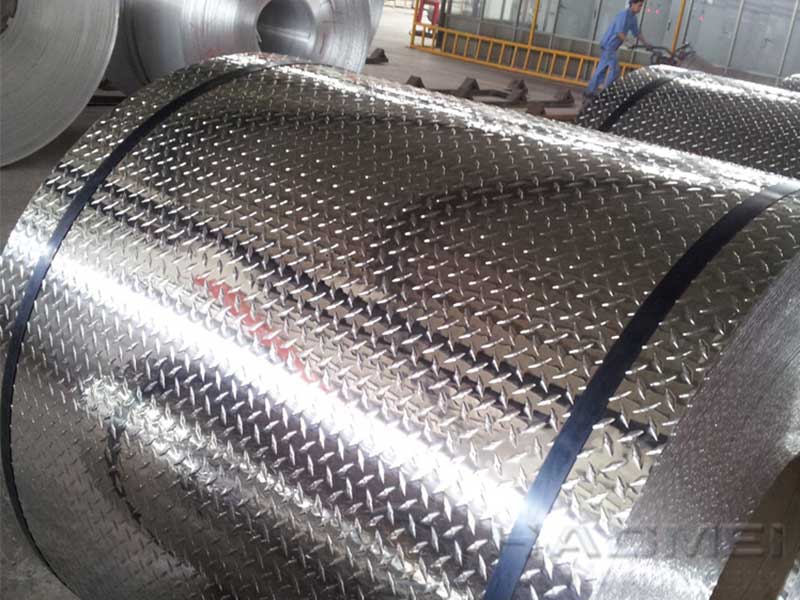

Stucco Embossed Aluminum

View DetailsSteel

- Aluminum stainless steel trans...

- Titanium Clad Steel Plate Shee...

- stainless steel aluminum clad...

- Copper-steel clad sheet plate

- aluminum steel triclad transit...

- Aluminimun and steel bi metal...

- The anode steel claw

- Aluminum Electrolyzer Anode St...

- Three-layer copper stainless s...

- Anode steel claw

- armoured armor clad steel plat...

- Aluminum steel explosion weldi...

- Explosion welding aluminum ste...

- Explosion Welding Aluminum Ste...

- copper clad steel sheet and st...

- Steel anode claws china suppli...

- Brass steel bimetal coil strip

- Aluminum Steel Electrical Tran...

- Process of Prebaked Anode Stee...

- Titanium clad steel plate for...